ENGINEERING & DESIGN

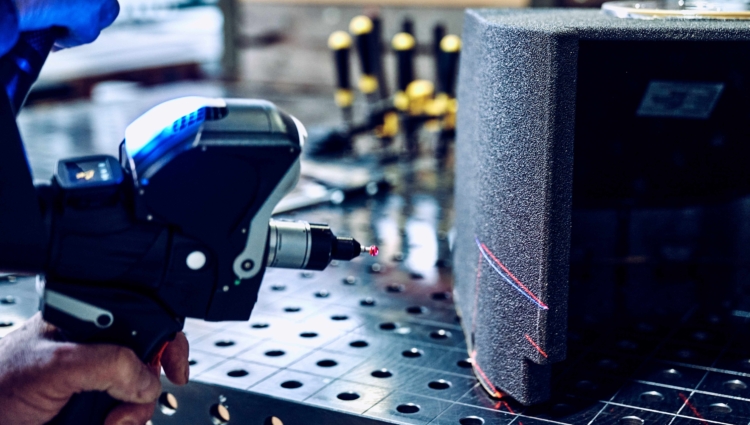

We work with the world’s most demanding industries to produce the world’s most advanced lightweight solutions.

LEADING ENGINEERS WORK FOR US.

WE PUT THEM TO WORK FOR YOU.

Integris Composites is a turnkey provider from concept development through field maintenance. Led by outstanding technical experts in a wide range of specialist fields, including production technology, technical design and chemical engineering; we specialize in both OEM and retro-fit integration.

Our teams have proven experience with large scale, complex projects within a variety of applications of our composite armor; summarized in statistical and modeling tools and an internal database containing 4000+ solutions. Our systems are internationally qualified to STANAG 4569, NIJ, VPAM, and other standards.

- PROJECT MANAGEMENT

- Systems Engineering

- Systems Test

- Systems Safety

- Electrical Engineering

- Software Engineering

Project Management

- Program management and IPT lead

- Successfully managed 12 month 1M+ systems integration effort meeting all deliverable milestones.

- Developed WBS and IMS to support programs

- Monthly reporting of program status and lite EVMS metrics

- Developed and attended all reviews including SRR, PDR and CDR including interim reviews as necessary

Systems Engineering

- Systems IPT

- Systems engineering management planning

- Requirements identification, decomposition & management

- Architecture & design

- Trade studies

- Operations concept

- Algorithm development

- Interface control

- Configuration management

- Design reviews

- System verification

- Environmental verification

Systems Test

- 6 m/s drop tower for impact detection sensor testing

- 10 m/s+ drop tower available

- High speed video Phantom v7

- Engineering

staff with ~40 years combined experience with vehicle crash & blast

testing in commercial automotive, military vehicles, and aviation.

Includes experience doing full scale helicopter crash with active system

at Langley Gantry. - Internal testing according to a variety of MIL, DEF, ISO and

DIN standards; ballistic and generic properties; including bonding,

adhesion, chemical resistance, low and high temperature testing. - Experience within field application and testing of vibration, UV resistance, salt & fog and other MIL 810 requirements.

Systems Safety

- Safety IPT

- Hazard identification, analysis, tracking & mitigation

- Risk assessment & reduction

- Safety assessment

- System safety interfaces

- Software safety

- Safety verification

- Incident reporting

Electrical Engineering

- Vehicle-level electrical system design as well as Line Replaceable Units (LRUs)

- Wiring, cable, and harness designs

- Circuit board schematic capture design and printed circuit board design (gerbers)

- Turn-key capability; design, manufacture, test & integrate all system hardware

- MIL-STD design understanding and experience

- Circuit boards; analog, digital, high-speed, high-power, and mixed-technologies

- EMI/EMC experience

- LRU automatic and manual testing

- System level; verification and validation of design

- Field test; design validation as well as customer support

Software Engineering

- Real-time embedded software design capability for mission critical timing requirements (~30 years’ experience)

- Graphical user interface capability for manufacturing and testing

- Test data processing capability to support manufacturing as well as end customer(s)